RivetRite

Rivet Rite @ Aerobolt, your Australian rivet specialist.

Australia's #1 Range of Rivets and Rivet Guns.

Rivet Rite @ Aerobolt. Comprehensive range of Structural Rivet & Standard Rivets options, including the the original Huck Magna-Lok rivet, through to standard rivets like the versatile multi-grip rivets. Make Aerobolt your one stop shop for all your riveting supplies with; brands you know & trust, award winning service, technical know-how, rivet testing services, value, and so much more.

What is a rivet?

Rivets are a popular mechanical fastener used to join two or more pieces of material. Essentially a rivet is composed of two components, a metal tube (body) & pin (mandrel). The pin is normally longer than the tube and designed to be pulled up through the tube whilst enlarging it in the process. This results in the expanded tube clamping the material between the two ends of the tube. There are numerous rivet types for virtually any application; from connecting your home’s guttering through to the cars we drive and the planes we fly. In fact, it is almost impossible to imagine today’s world without rivets.

What are the key advantages of Rivets?

Rivets are extremely popular because they are fast & easy to use, and work well with many different materials.

- Blind side assembly for fast installations, as access to the rear is not required

- Very resilient, forming a mechanically activated permanent joining solution.

- Easy to learn air, cordless, and manual tools that require minimal effort and training.

- Flexibility, wide range of types and materials to suit most applications.

- Fast inspection and maintenance, no expensive equipment for quality control.

What are the main rivet types?

Here we list the common types of blind rivet categories we stock; you can also review on our website for further information. Your selection criteria should be based on the application connection you believe is required, whether your job involves installing metal roofing, guttering or building a truck trailer.

Open end rivet (Also known as pop rivet or blind rivets).

Commonly referred to as "pop rivets", open end rivets are a low-cost fastener available in a range of materials, including different combinations of materials. The most common ones include: steel & aluminum, all steel, all aluminum, stainless & steel, all stainless, nickel & copper. A popular choice with many of our building construction customers.

Closed end rivets (Also known as sealed rivets).

Closed end rivets are like open ended pop rivets however they have a cup shaped end configuration that eliminates water ingress from within the body of the rivet, but not between the outside of the body and the material. Many customers purchase these items believing they are waterproof, unfortunately this perception is not 100% correct.

Multi-grip rivets

A strong & highly flexible rivet due to its extended material grip range. The multi-grip rivet is our strongest standard rivet choice, for many customers this rivet helps reduce stock options as one multi-grip rivet replaces a few open end rivets. We find this assists to reduce cost and minimise operator errors with many of our steel fabrication customers.

Tri-fold Rivet

Aluminum tri-fold rivets are designed for the assembly of lightweight materials such as fiberglass, plastics, thin steel sheeting & composite material. This rivet forms a propeller shape anchor connection on the blind side of the material without damaging it.

Peel Rivets

Peel rivets are also ideal for the joining of softer material such as timber, plastic, rubber, fibreglass, and laminates. Upon installation, the rivet body splits into petals that bends outwards, like peeling a banana. The petals bend out and contact the blind side of the material, creating a large anchor head.

Groove Rivets

Groove Rivets are designed to be installed within a hole as they infuse themselves into the material, making them ideal for soft materials such as timber, plastics & other fibrous material. When set correctly, the annular rings around the body will expand into the surrounding material.

Structural rivets.

Structural rivets differ from standard rivets because they are designed with a locking mechanism that interlocks the body, pin, and the material upon installation. Structural rivets are commonly referred to as Huck rivets, or Monobolt®. Structural rivets are used in critical applications which makes it important you select a quality product. We are Australia’s number one distributor of Huck brand rivets and can assist with application advice, feel free to call or email us for an installation review.

Self-piercing rivets

This is another category of rivet, a self-pierce rivet joins two or more layers of material by piercing the top layer of material and then flaring out at the bottom layer, forming a mechanical interlock. As the name suggests predrill holes are not required, allowing for a rapid, strong, fastening solution that would suit numerous applications. This item is not on our site, however we do stock them.

How do I select the right rivet?

Before selecting the right rivet, you will need to consider material, size, and material grip range.

Materials.

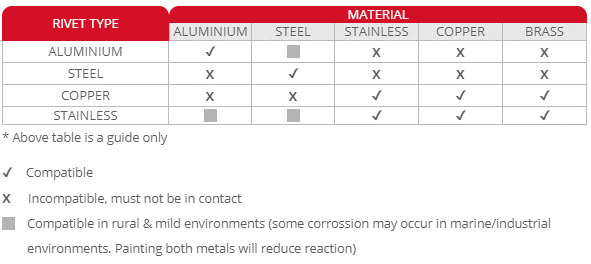

Ensure the rivet material is compatible with the material being joined to avoid galvanic corrosion. As a rule, avoid using aluminium and stainless steel together, we recommend keeping the metal material like for like for maximum life. Stainless with stainless, aluminium with aluminium, etc.

When reviewing material, you will also need to consider environmental factors, such as extreme temperatures or salt sprays. See the table below as a general guide.

Diameters & Hole Size.

The size of the rivet diameter & the drill hole size is critical for success. If the rivets diameter is too small for its hole, then the gap may cause installation failure. Referring to the hole diameters before drilling is an easy way to avoid issues later.

Refer to the table below covering diameters and corresponding hole sizes.

Material Grip Range.

The material grip range refers to the material thickness or the depth the rivet can be effectively installed. For example, if two 1.5 mm plates/items need to be riveted, a blind rivet with a material grip range between 2- 5 mm is required. Best practice dictates that the middle grip range of a rivet should be used and not the minimum/maximum sizes. This assists in achieving correct shear and tensile strength whilst ensuring the longevity of the rivet. Please note that the grip range is not the length of the rivet as many people mistakenly believe the length is the amount of material the rivet will pull up.

Listed below we have a table listing standard blind rivet material grip ranges and their corresponding grip code.

Head type

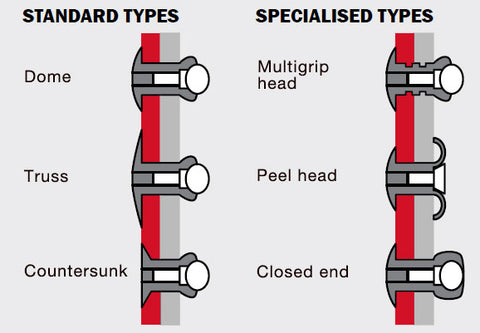

The rivet head type assists in holding the material together and enhancing its appearances. Dome heads sit proudly above the material, whilst large flange or truss head is a shallower broader head profile & suited for thin or soft material items like rubber or fibreglass. The countersunk option provides a flush neat finish subject to countersinking the hole, allowing the head to sit level with the surrounding material. The image below covers the typical head types.

Frequently Asked Rivet Questions.

How do I order rivets?

You'll need to know the body & pin/mandrel material, head type, diameter and grip range before you order. Using the codes for each of these variables, you can derive a product code such as:

In the above example, we have:

A = Aluminium Body (S = Steel, SS = Stainless)

B = Button/Dome Head (T/L = Truss/Large Flange, C = Countersunk)

6 = 4.8mm (3/16") Body Diameter (4 = 3.2mm, 5 = 4.0mm, 8 = 6.4mm)

6 = 7.9-9.5mm Grip Range (See grip codes number table in previous section)

S = Steel Pin/Mandrel (SS = Stainless, A = Aluminium)

How do I remove a rivet?

Removal requires the destruction of the rivet, the best method is to drill it. You will need, a drill, drill bit, long nose pliers, & safety accessories such as glasses and gloves.

Steps: Use your safety glass & gloves before starting the drilling process. Place the drill bit against the rivets’ center pin and drill through the body at a low but steady speed. Once drilling is completed, pull the rivet off with your long nose pliers.

How do I install rivets?

To install a rivet, pre drilling of holes is required. Load rivet’s pin tail section into rivet gun. Insert rivets body into hole and activate gun. Upon activation the head of the rivet is pushed against the outer surface of the tool, whilst the tool pulls up the central pin. As a result, the bottom portion of the rivet compresses, and expands on the blind side. This expansion increases until it reaches approximately one and a half times the size of the original diameter. Resulting in a larger surface in which the two materials are effectively fastened together.

How does a rivet work?

Essentially a rivet is composed of two components, a metal tube (body) & pin (mandrel). The pin is normally longer than the tube and designed to be pulled up through the tube whilst enlarging it in the process. This results in the expanded tube clamping the material between the two ends of the tube.

Which is the best rivet gun?

Selecting the correct rivet gun depends on several factors that relate to your specific requirements, rivet gun section is covered in the blog; Ultimate Guide to Rivet Guns.

Which rivet is used in heavy structural work?

Structural rivets or Huck rivets are used in structural applications because of their high tensile and shear strength. Designed with an internal locking mechanism that provide great clamping force and have ability to carry heavyweights. Structural rivets are predominantly used in critical applications and the quality of the product is important.

What is the difference between the pop rivet and blind rivet?

Many customers ask this question and the short answer is there is no difference. They are two labels for the same item, a blind rivet means you do not need access to the other side of the material, or you can't see the other side of the material. Also known as pop rivets because it is the brand name of the original rivet company.

Which is the strongest rivet?

The strongest rivet are the high strength structural rivets. There are numerous options and selection is dependent on your application.

Can I get coloured rivets?

Yes, painted rivets are available. They cost a little extra compared to the mill (raw) finish and are available in a wide range of colours. Refer to the Colorbond ® colour chart for your selection.

Can you assist me with rivet selection?

Sure, product selection can sometimes be a little tricky, the Aerobolt team can assist with the selection by either calling us on 02 9755 3747 or contact us.

Do you deliver rivets throughout Australia?

Yes, we can deliver Australia wide through our network team of courier companies. In Sydney we offer our customers same day delivery if you order before 10.00am or the next day. Deliveries to regional New South Wales or major Australian cities such as Melbourne, Brisbane including regional South Eastern Australia are either next day delivery or 2 days turnaround.

Why have my rivets failed?

There are several reasons your rivets have failed. The issue could be a dodgy rivet or an installation issue. Either way we offer a wide range of technical services, including rivet test lab services. We have teamed up with a NATA approved lab that undertakes rivet testing services. Should you have a rivet failure, let us know so we can review your application and or have your rivets sent to the NATA approved lab for laboratory rivet testing.

Why have my structural rivets failed?

Structural rivets work a little differently to standard rivets, as there is an internal mechanism that locks a portion of the pin (mandrel) inside the rivet's body. This creates an additional layer of material that assists in increasing the rivets strength, whilst interlocking with the material.

There are several reasons your structural rivet has failed. The issue could be a dodgy rivet or an installation issue. Either way we offer a wide range of technical services, including rivet testing services. We have teamed up with a NATA approved lab. that undertakes laboratory rivet testing services. Should you have a rivet failure, let us know so we can review your application and or have your rivets sent to the NATA approved lab for laboratory rivet testing.

Rivet Rite Summary.

Rivets offer superior fastening capabilities for both heavy-duty and light fabrication applications. A rivet in one form or another has been used by people for numerous centuries and it is hard to imagine a world without rivets. They are found in the metal roofing and guttering that protect our homes, to the air conditioners that make us more comfortable to the cars we drive, the planes we fly and the ships we sail. Wherever there is a metal-to-metal application there is bound to be a rivet in use. Rivets are the number 1 blind side fastener in use and its applications are endless.

At the conclusion of this blog, it is evident that rivets are very important and as well as crucial in fastening processes. Irrespective of the rivet type required for your project, be assured with a bit of planning your project will end up as a successful one. Here at Aerobolt we have a comprehensive range of rivet product categories and can assist in your application, simply call us on 02 9755 3747 or contact us for all your riveting requirements.

Copyright © 2024 Aerobolt Australia Pty Ltd. All rights reserved.